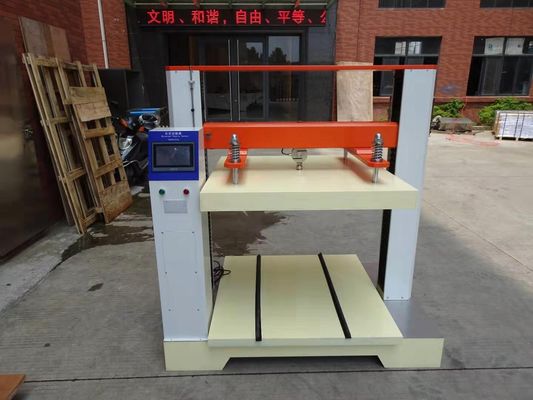

Product introduction:

It is the basic instrument (i.e., packaging testing equipment) for corrugated box compressive strength performance testing, which is suitable for compressive strength test, standard test and stacking strength test of various corrugated boxes.

Product features;

1. After the test is completed, there is an automatic return function, which automatically judges the crushing force and automatically saves the test data

2. Three settable speeds, full Chinese LCD display operation interface, a variety of units to choose from.

3. It can input relevant data and automatically convert the compressive strength, and has its own packaging stacking test function; The force and time can be directly set, and the machine will be automatically stopped after the test is completed.

4. Three working modes:

Strength test: the maximum pressure resistance of the box can be measured;

Fixed value test: the overall performance of the box can be tested according to the set pressure;

Stacking test: According to the requirements of national standards, stacking tests under different conditions such as 12 hours and 24 hours can be carried out.

Meet the standards:

GB/T 4857.4-92 Packaging ,Transport packages, Pressure test methods

GB/T 4857.3-92 Packaging, transport packaging, static load stacking test method

Hardware performance characteristics:

1. 32-bit embedded processing chip, fast instruction cycle;

2. The strain measurement accuracy > four gears, that is, the resolution > 20,000 yards;

3. The software coefficient is used for sub-file calibration (correction). Effectively correct the linearity of the sensor;

4. Quadruple frequency photoelectric encoder forward and reverse two-way counting, high resolution;

5. The display adopts 192×64 dot matrix large-screen monochrome LCD, which can display more information;

6.1 RS232 serial port, can be connected to other devices;

7.1 channel printing parallel port, can be connected to micro printer or dot matrix printer;

8. Eight control buttons (5 function keys, 3 multiplex keys), easy to operate;

9. Display function: the maximum force in the test process can be automatically displayed and memorized at the end of the test;

10. Save output: up to 20 test results can be recorded.

Random standard accessories

1. A one-year warranty and a Chinese operating manual;

2. 2 rolls of printing paper will be given as a random gift;

3. A high-precision load sensor;

4. One micro printer (can print test report).

5. 1 power cord;

Safety Devices:

1. Stroke protection: set to the beginning of the upper and lower limit protection to prevent exceeding the preset stroke;

2. Force protection: the system can set the maximum force value to prevent exceeding the calibration value of the sensor;

3. Emergency stop device: there is an emergency stop on the right side of the base, which can deal with emergencies.

Job Specifications:

1. Room temperature: 25°C;

2. Power supply voltage: 220V, the power supply should be reliable to ground;

3. The working environment is clean, there is no strong vibration source, and the main engine is stable.

Note: The above parameters are standard models, if there are special requirements, our company can design the most suitable plan according to your requirements!

Technical Parameters:

Capacity selection: 0~1T(Can be customized according to customer requirements)

Accuracy level :Level 1

Control method:Touch screen

Strength unit switching kgf,gf ,N,kN,lbf

Stress unit switching MPa,kPa,kgf/cm2,lbf/in2

Units of displacement mm, cm, in

Force resolution 1/100000

Display resolution 0.001N

Machine stroke 1000

Platen size 1000*1000

Speed of experimentation 5mm~100mm/min can be input speed arbitrarily

Software Features Chinese and English languages are interchanged

Shutdown mode Overload stop, emergency stop button, automatic stop for specimen destruction, and automatic stop for upper and lower limit setting

Safety devices Overload protection, limit element protection device

Machine power AC inverter motor drive controller

Mechanical systems High-precision ball screws

Power supply AC220V/50HZ~60HZ 4A

The weight of the machine About 650KG

Performance characteristics The percentage break value can be set, the machine can be stopped automatically, you can enter the menu to select 4 different speeds, you can get 20 results and view the average of all test results and a single result

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!